Corrugated Boxes: A Eco-friendly Packaging Choice

The corrugated boxes packaging is not only an environment-friendly and renewable packaging type but is also highly cost-effective for businesses, making it a popular choice across industries. Indian Corrugated Case Manufacturers’ Association (ICCMA) estimates that the industry manufactures 7.5 million tonnes of corrugated boxes in India and has a market size of Rs 30,000 crore. India’s corrugated box manufacturers mainly cater to FMCG, pharmaceutical, and e-commerce industries.

Also Read: An Out of The Box Idea For An Out of Gauge Cargo

What are corrugated boxes?

Corrugated boxes are made up of a few layers of material rather than just a single sheet. They comprise three layers that include an inside liner, an outside liner, and a medium that goes between the two, which is fluted. The liner board is flat, thick paper that looks smooth and makes up the two outside surfaces of the box. The corrugated part of the box is the middle layer with the air grooves called the medium. This grooved material, also referred to as the flute, comes in several measurements, and boxes can be created with several different flute profiles. Larger flutes provide better cushioning and greater vertical compression strength, while smaller flutes provide structural integrity, enhanced graphics capabilities, and lower overall thickness.

Also Read: 5 Benefits of Using Corrugated Packaging

Corrugated boxes are made up of a few layers of material rather than just a single sheet. They comprise three layers that include an inside liner, an outside liner, and a medium that goes between the two, which is fluted. The liner board is flat, thick paper that looks smooth and makes up the two outside surfaces of the box. The corrugated part of the box is the middle layer with the air grooves called the medium. This grooved material, also referred to as the flute, comes in several measurements, and boxes can be created with several different flute profiles. Larger flutes provide better cushioning and greater vertical compression strength, while smaller flutes provide structural integrity, enhanced graphics capabilities, and lower overall thickness.

Types of corrugated boxes

Several components are put together to make a corrugated box, making it easier to customize corrugated boxes design and corrugated box sizes based on individual business needs.

Board types

Board types

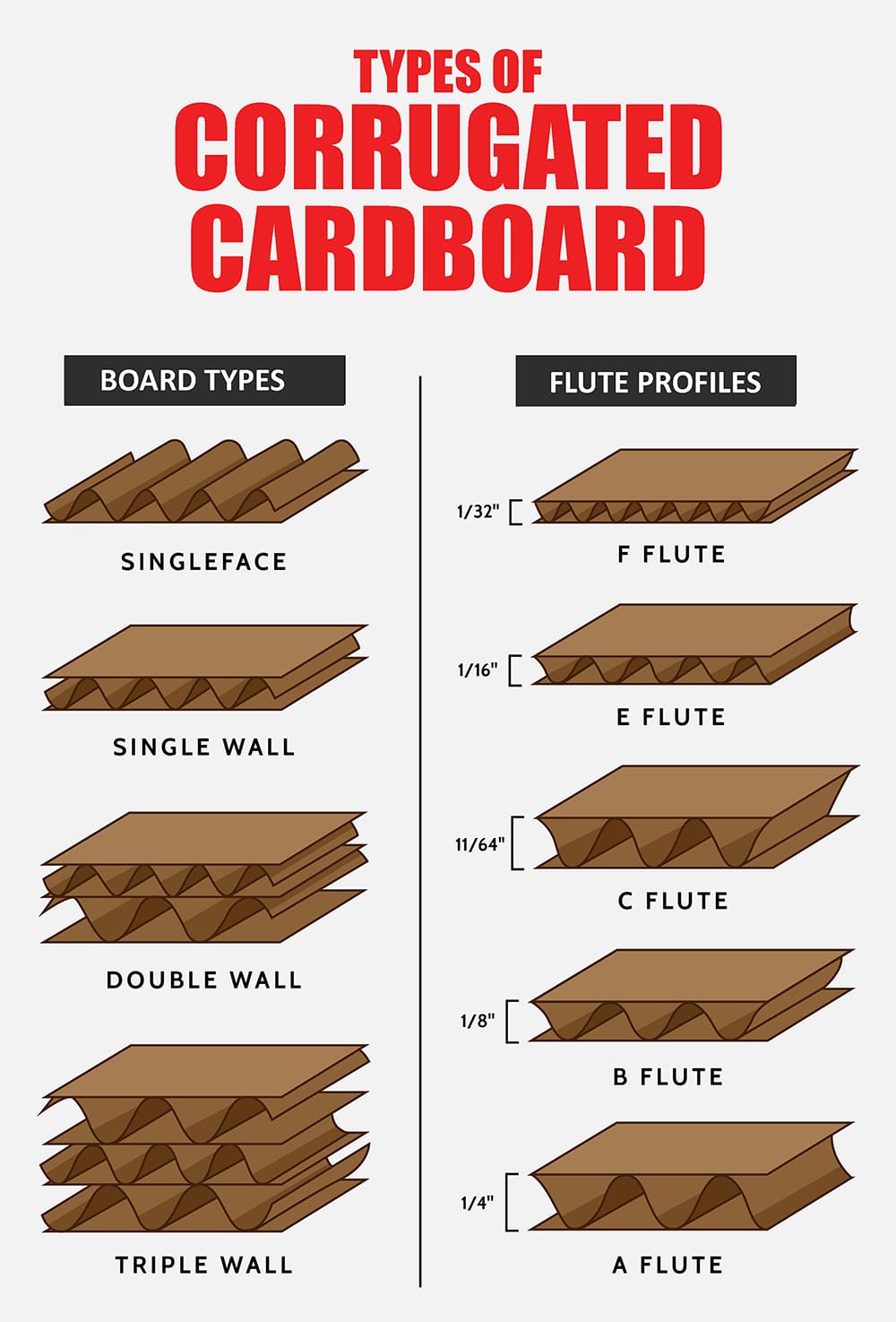

There are four types of corrugated boxes—single-face, single wall, double-wall, and triple wall.

1. Single-face

This type of corrugated sheet consists of a single flute and one or two sheets of linear board. The flute is stacked to the linear board. They are normally in the form of sheet rolls and are mainly used to wrap around the product for protection or cushioning.

2. Single wall

This kind of corrugated box consists of a single sheet of a corrugated medium that is glued and placed between two sheets of liner board. It is mainly used in the retail industry and is a good material to create shipping boxes.

3. Double-wall

This kind of corrugated box consists of a single sheet of a corrugated medium that is glued and placed between two sheets of liner board. It is mainly used in the retail industry and is a good material to create shipping boxes.

4. Triple wall

The strongest of all types of corrugated boxes is made of three layers of corrugated medium and four layers of liner board. They are used in the packaging of industrial parts due to their durability and higher burst strength.

Also Read: 6 Reasons Why You Must Use Custom Industrial Packaging

Flute Profiles

The five most common flute profiles used are A, B, C, E, and F, with ‘A’ being the original flute design. The thickness of the walls and stacking strength are determined by the flute size. With ‘A’ being the largest size, as you go through B, C, E, and F flutes, the thickness is reduced resulting in a thinner board.

Board Grade

The corrugated board is categorized as either Mullen or Edge Crush Test (ECT). These two board grades have very different applications as ECT measures how much stacking strength or pressure a box can withstand before being crushed and Mullen value determines the amount of pressure a box can withstand before bursting or being punctured.

Also Read: Pronk Multiservice Supplied Customized Corrugated Packing Solution to a Loyal Customer

What are the benefits of corrugated boxes?

• Customization

Corrugated boxes are versatile and customisable making it possible for corrugated boxes suppliers to design the best packaging to fit your product perfectly. It also ensures an eye-catching advertisement platform to showcase your products to consumers.

• Eco-friendly

Consumers and governments are emphasising more on sustainable packaging. The increasing demand for environment-friendly packaging has made corrugated boxes quite popular as they are recyclable and reusable.

Corrugated boxes can be used for packaging assorted products irrespective of their size, shape, or weight. Their feasibility, recyclability, reusability, and cost-effective alternative to other packaging materials make it a preferred packaging choice.